Lean, Digital, Green, Resilient – no company can evade these challenges. But how do these top topics relate to one another and what must be considered during implementation? The Staufen consultants Dr. Michael Feldmeth and Christian Sprenger explain in an interview why the structure and sequence decide the success or lack of success of a transformation.

In conversation with Michael Feldmeth, Principal and Christian Sprenger, Partner at STAUFEN AG

Can you please explain the current Staufen in brief?

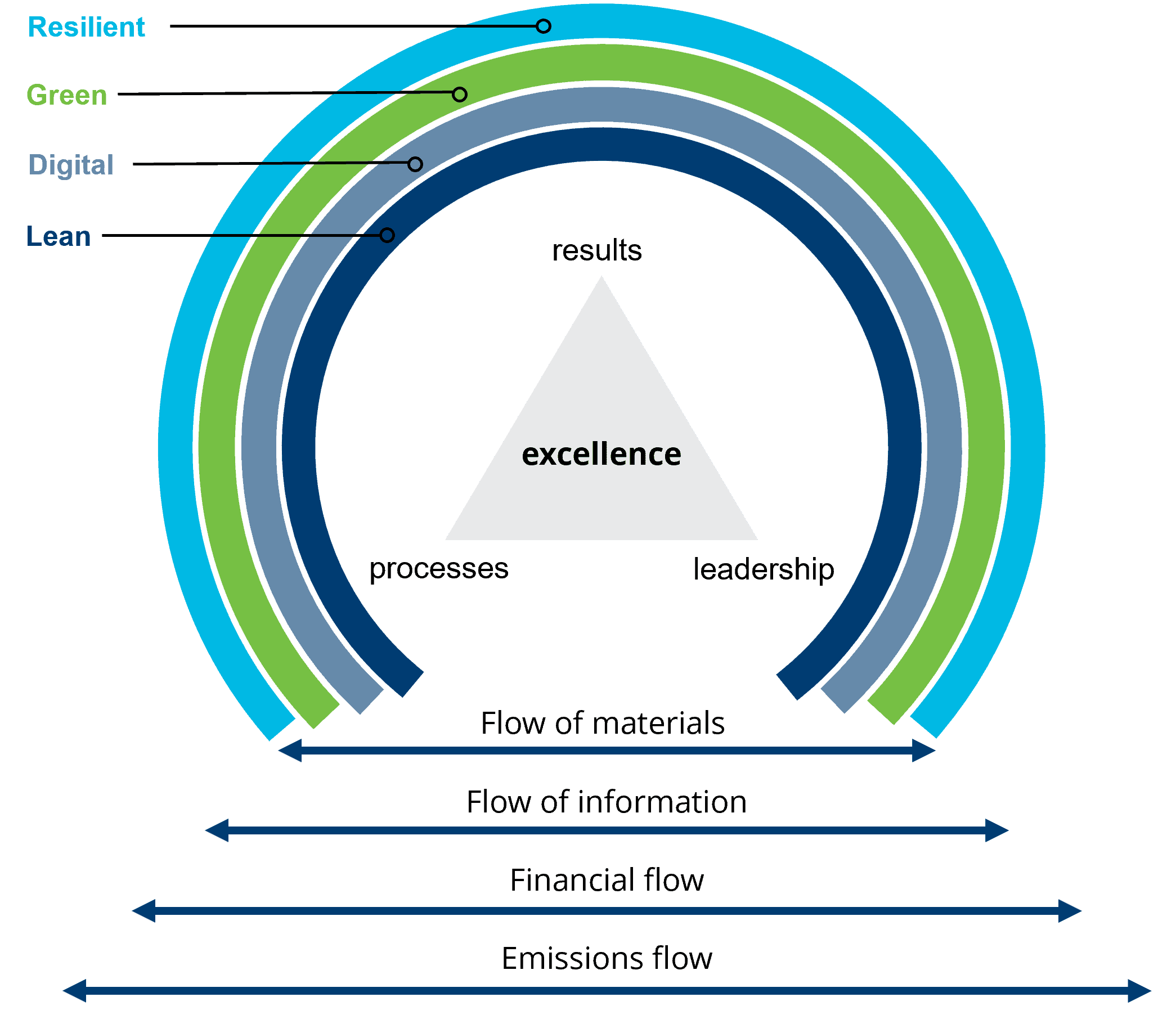

Feldmeth: The figure shows our holistic consulting approach and indicates the broad spectrum of topics with which we can assist our customers. The focus is on our mission: excellent processes, excellent leadership, and as a result, excellent results. We pursue this ideal and this is also our customers’ goal. Along the way, the four elements lean, digital, green, and resilient play a central role, both as drivers and tools for optimally-configured end-to-end processes.

What characterizes the individual elements lean, digital, green, and resilient?

Feldmeth: The four overarching topics and consulting fields build on one another. Lean Management in the first round forms the basis for state-of-the-art end-to-end processes. Basic topic such as the reduction of waste, focus on customer benefit, and the reduction of lead times remain current in the industrial environment, precisely in this era of digitalization. Using digital tools and building on lean, we can achieve additional process improvements and performance leaps. Increasingly important today is to be green, to focus on resource-sparing and sustainable production, and also on core elements of Lean Management and the area of resilience. This is where the focus is on adaptability and company-spanning production networks. With regard to optimized end-to-end processes, we concentrate on the entire value stream and optimize the various flows at the company. Here, in addition to the flow of material and information, we examine the monetary consequences of individual activities on the result and liquidity, as well as the emissions and management of scarce resources.

Should the consulting fields always be run through in a particular order?

Sprenger: The consulting approach must be selected individually for each customer, but our framework provides a sensible order. That is to say that we generally begin with lean and optimize the processes. For only lean processes can produce lean digitalized processes. If the company is digitalized efficiently and effective ly, the journey toward green and/or resilience can continue. The first two elements form the basis and rely in their implementation heavily on the other topic areas green and resilience. Given the topics with which they are confronted, many CEOs don’t care whether the issue is compliance with reporting duties with regard to sustainability or the still-fragile supply chain networks. But without lean and digitalized processes, there is no good solution for these topics.

So you think that companies should proceed step by step instead of jumping feet-first into the individual topics green and resilient?

Feldmeth: Precisely, and with this order and framework, we have created a structure that can help companies organize the buzzwords of the hour strategically despite the hectic atmosphere. What’s important, what can wait a while? This way, we help companies assess themselves realistically and to see which fields of action should take priority in the current situation.

For current topics such as the supply chain act and sustainability reporting, companies have to act fast, however. What procedures do you recommend in such cases?

Sprenger: Regardless of whether or not a company has already implemented efficient and digitalized value creation according to lean principles, there are duties that may not be put off. Compliance with legal requirements does not automatically mean that a company is already really sustainable or resilient. That’s why I advise companies that are not yet digital or lean to set priorities. The clear advice: first ensure that the base is solid and then prioritize the topic areas green and resilient. With this structured process, companies will be able to succeed must faster and more efficiently. Here’s a simplified example: if you slim down your S&OP processes across the boards using lean criteria and then digitalize, you will automatically be more resilient since you can synchronize your demand and supply curve better. At the same time, you will be more sustainable since you significantly reduce inventory levels and therefore can produce with fewer resources.

So such a procedure brings only benefits?

Sprenger: Yes, the biggest qualitative and quantitative optimization can be achieved with a consistent examination of these topic areas across the order framework. Essential here is the strategic orientation provided by the management, which orients the existing capacities uniformly and prioritizes the topic areas. Otherwise, you’ll have a patchwork quilt that solves problems here and there, however cannot exploit any interface-spanning synergy effects since there is no focus on end-to-end processes or customer-centered action.

THE AUTHORS

Michael Feldmeth

Project Manager

STAUFEN.AG

Michael Feldmeth

Project ManagerSTAUFEN.AG

Michael Feldmeth has implemented various Lean projects in the automotive industry as well as in mechanical and plant engineering. His projects included the restructuring of the entire order processing. The focus of the projects was the optimization of the production processes as well as the associated administrative processes. Due to the production of cooling systems and special machines, he was able to achieve a significant increase in efficiency and flexibility of production by reorganizing the manufacturing according to Lean principles and by training the employees. Most recently, he worked at Robert Bosch GmbH in the Central Department for the Development and Coordination of the Bosch Productions System. He was responsible for the further development of the production system according to the future requirements of the manufacturing industry. Michael Feldmeth has been working for Staufen AG since 2014. Since 2019 he is employed as a Project Manager.

Read more

Christian Sprenger

Partner

STAUFEN.AG

Christian Sprenger

PartnerSTAUFEN.AG

After finishing his studies of business administration with focus on Corporate Finance and Management at the universities of Tübingen and Mannheim Christian Sprenger worked for the Wintergerst Societät für Unternehmer-Beratung for four years. There he accompanied various restructuring, growth and reorientation projects as well as M&A processes, primarily in the area of production companies. Christian Sprenger’s expertise especially lies within the field of Working Capital Managements as well as the analysis and development of integrated financial plans and financial modeling.

Read moreYou might also be interested in

Study: Future Industry

How the industry is positioning itself for the future! Our new study on the topics of digitalization, efficiency, sustainability and resilience.

Read more

Cost pressure: “Cost cutting alone is too short-sighted and certainly not sustainable!”

All signs in the German economy are pointing to recession. So where can companies start to build up more resilience despite the challenges and enormous cost pressure? What can they do to strengthen their competitive strength over the long term? Staufen experts Christian Möllers and Christian Sprenger respond to the most pressing questions.

Read more

Performance Improvement & Restructuring

Companies face special challenges when confronted with crisis situations such as an upcoming restructuring or reorganization. These phases are often defined by stressful in-house discussions about the potential causes of the crisis, a lack of clarity about the necessary countermeasures, insecurity about future perspectives, and critical conversations with banks and investors about further economic development and financing. In times such as these, expedient and rapid decisions and consistent actions are needed. Within the shortest time possible, our consultants provide comprehensive transparency by performing a technically solid and objective assessment of your baseline situation.

Read more