The future is traded on the stock market, but the future is developed in start-ups. And it looks good. To find out how the Weconomy winners presented here will change production processes in german industry, let us take a look behind the factory gates of a fictional company in 2025. Mario L. works in the warehouse, and is responsible for picking. In his office adjacent to the hall, there is a lift truck – more for sentimental reasons than out of necessity. It reminds him of the noisy, sweaty days before digital warehousing was introduced.

WECONOMY brings together innovative, technology-oriented start-ups and established companies. The start-up initiative offers access to valuable contacts and many opportunities to exchange ideas with experienced professionals and managers.

The competition is organized annually by Wissensfabrik – Unternehmen für Deutschland e.V. in cooperation with UnternehmerTUM, Europe’s leading center for innovation and start-ups, and Handelsblatt.

Here we present three current award winners:

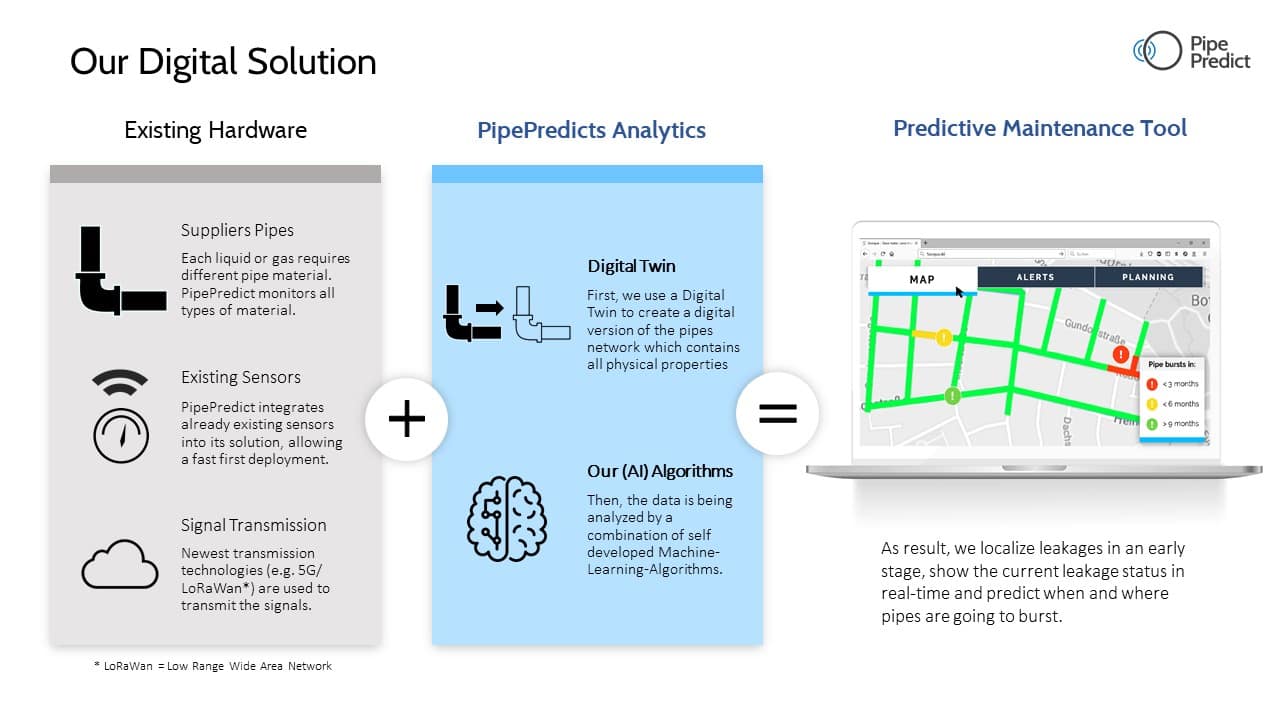

PipePredict GmbH issues warnings about pipe bursts. To achieve this, the start-up from Darmstadt creates a digital twin that digitally maps supply networks and their condition using supplied sensor data.

LiGenium GmbH from Chemnitz is a manufacturer of wooden load carrier

in logistics. The start-up is developing modern wood-based materials for use in internal logistics.

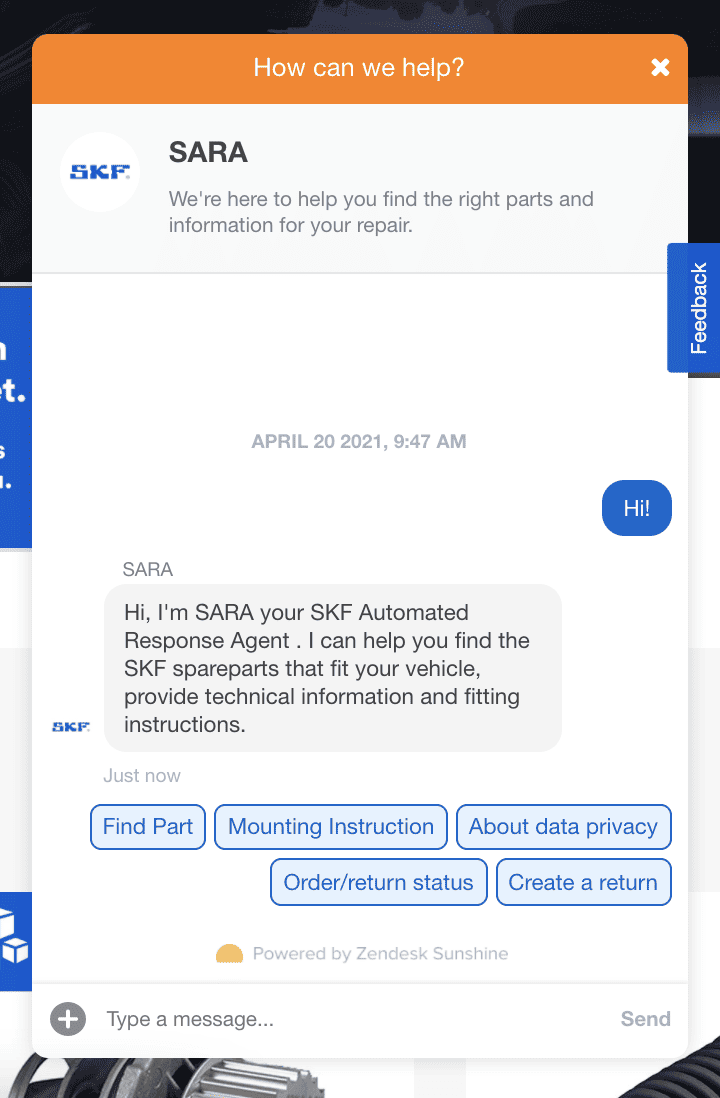

BOTfriends GmbH specializes in chat and voice bots. The start-up from Würzburg has developed a platform with which chat and voice bots can be created, customized and controlled without any programming knowledge.

LiGenium GmbH

“As a material, wood is very light and yet strong, you just have to know how to handle it. Wooden load carriers are ideal for transporting sensitive goods, because the goods are not electrostatically charged and the soft structure of the wood ideally absorbs shocks. Unlike other lightweight materials, such as carbon, wood is also sustainable. In production, we save up to 95 percent of CO2 compared to traditional warehouse logistics manufacturers.”

DR. RONNY ECKARDT

Founder LiGenium

ANGELA GRIMMER

Founder LiGenium

ANGELA GRIMMER AND DR. RONNY ECKARDT founded LiGenium together with Dr. Sven Eichhorn and Christoph Alt. The business economist and the three engineers met at the Chemnitz University of Technology in a research group focusing on wood.

Thanks to comprehensive digitization and reorganization, ideas previously discarded as “future dreams” can now be implemented: recording and processing real-time inventories, intelligent and process-supporting automation, predictive AI analyses, and helpful, voice-bot-based interaction with the inventory management system. The result: more efficiency, safety, sustainability and even job satisfaction.

Because converting the old building – as a positive side effect, so to speak – also greatly improved the general mood and comfort in the company. Where heavy steel trolleys once rumbled through the hall with deafening sound, LiGenium’s lightweight, wooden transport trolleys and trailers now glide on specially manufactured roller conveyors with an innovative plug-in system.

Originally, the wooden transport containers were chosen because their modular design allows them to keep up with the flexibility of the new merchandise system and can be quickly adapted to new needs. Moreover, unlike the old steel containers, the wooden containers do not act like Faraday cages. This was crucial in the group-wide conversion to Industry 4.0 because it made it possible to track goods labeled with RFID chips in the warehouse.

PipePredict GmbH

Working in three shifts requires a smooth process without disruptions. When it came to converting the hall, however, the plant management could not implement a greenfield solution, but rather had to adapt the plans to the existing brick walls, which were 100 years old. At the same time, the adjacent production was not to be endangered. One challenge here is to ensure the reliable supply of fresh water for the manufacturing processes and safe

discharge of wastewater into the company’s own wastewater

treatment plant.

Before the rebuild, the old pipe system was considered to be one of the greatest weak points because, due to the structural conditions, the pipelines were in the immediate vicinity of the transport roller conveyors controlled by Mario L. Leakages from the pressurized service water system repeatedly disrupted order picking, and the Group’s management also wanted to consistently curb water wastage. This was no longer acceptable for economic reasons and the condition was also not sustainable. The company had finally committed itself to production in accordance with ESG guidelines and, among other measures, introduced wood storage logistics for this reason.

“In Germany, up to 10 percent of fresh water simply seeps out piping systems into the environment. Something has to be done. Our software helps to inspect pipe systems and identify damage. To do this,the first step is to create a digital twin that is supplied with sensor data. If there are any abnormalities, an alarm is triggered immediately. In the next step, we are working on predictive maintenance. This allows us to predict leaks before they occur.”

CHRISTOPHER DÖRNER is responsible for business development at PipePredict. He founded the company together with Valerie Fehst (product development)

and Tri-Duc Nghiem (product engineering).

To solve pipe problems once and for all, the company has therefore switched to forecasts from PipePredict. With the new analysis tool, the “ticking time bombs” are identified because the system can detect possible leaks in advance. Mario L. first heard the keyword predictive maintenance in connection with the new CNC machines in the production hall. Here, however, there was now a solution in which an old, existing system could be proactively controlled using artificial intelligence.

The data that feeds the AI comes from various pressure, feed, and flow sensors, all of which were installed at some point in the past 20 years. In the past, however, the data was not intelligently linked, which is why an independent factory team was always busy gathering individual pieces of data, making manual inspection rounds, and stopping production to locate possible leaks using electroacoustic tools.

With predictive AI, time-consuming maintenance tasks remain at a minimum, and instead there is 24/7, real-time monitoring that reports problems early on. And if service on the pipe is really necessary, it can be quickly located. In most cases, the software can narrow down the critical point to within a few meters. Mario L. is happy that he can once again finish work on time and head home with peace of mind knowing that order picking will continue without a hitch.