The topic of climate protection is now being taken very seriously by the manufacturing industry. Political climate protection targets at a global and national level contribute to this. But the market is also increasingly demanding accountability for the climate relevance of products and companies. This is most clearly illustrated by announcements from many major corporations that strive for so-called climate neutrality in the coming years. As a result, supplier companies are also being held accountable. It starts with the question of what the balance of greenhouse gas emissions looks like and continues with discussing plans to reduce those emissions. Figures and appropriate measures – this is what the focus will be in the coming years.

But even providing adequate figures is a difficult task. The Greenhouse Gas Protocol, an initiative of various non-governmental organizations, has become the standard for reporting a company’s greenhouse gas emissions. Not all of it makes sense or has proven. But t basic aspects are applied around the world. Scope 1 Emissions, for example, refer to direct emissions of greenhouse gases – primarily carbon dioxide – i.e., at the companies’ sites. This is the easiest to determine as it is calculated based on the consumption of fossil fuels.

Scope 2 Emissions are indirectly related to externally purchased energy, in particular electric power. Here balancing becomes more difficult: Do you calculate with the data from energy suppliers or with the national average values, the so-called electricity mix? There are good arguments for both, or objections to both. However, companies have the most problems with accounting for other emissions, e.g., in the supply chain or in the use phase of products. They are referred to as Scope 3 Emissions. For downstream emissions, there is no getting around a Product Carbon Footprint (PCF), which also includes the use and disposal phase. That can only be seriously prepared for individual cases and is a science in itself. For this reason, there are also separate standards for this, e.g., ISO EN DIN 14067.

Mario Schmidt

Physicist, environmental scientist and professor of ecological business managementPforzheim University Read more

MARIO SCHMIDT

Scientist and professor of

ecological business management

Pforzheim University

Physicist, environmental scientist and professor of ecological business management at Pforzheim University. He heads the Institute for Industrial Ecology (INEC) and is a member of numerous com-missions on sustainability, climate protection and resource efficiency.

Large emissions mostly occur when raw materials are extracted in distant foreign countries

In the supply chain, on the other hand, the problem arises that information often has to be obtained from hundreds or, in the case of large companies, even thousands of suppliers, and this on an international scale. Even then, you would only have figures from direct suppliers, so Tier 1. But what about the upstream supply chain to the end? These data elude any practical collection, but they are highly relevant because a large portion of emissions mostly occur where raw materials are extracted and processed in distant foreign countries, often with moderately efficient technology and using fossil fuels.

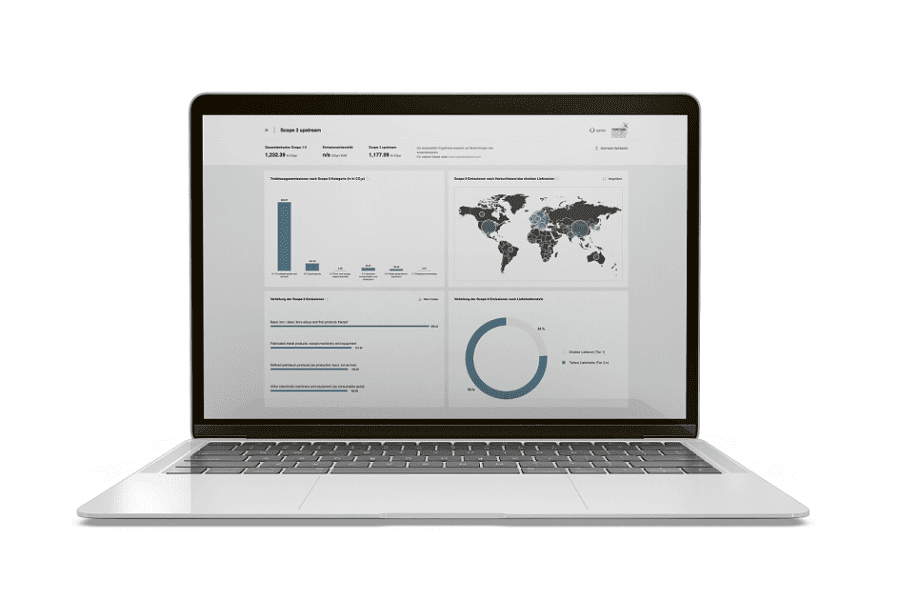

But there are methods to estimate emissions in the supply chain. For this purpose, international trade data and country-specific emission balances are used. The Institute for ndustrial Ecology at Pforzheim University, together with the Hamburg-based consulting firm Systain and the Karlsruhe-based think tank Industrial Resource Strategies, has developed a free web-based tool that makes it easy to determine emissions in the supply chain. The “scope3analyzer” was released in spring 2022. The tool was supported with funds from the state government of the German state of Baden-Württemberg.

In the scope3analyzer, a company can enter the purchasing volume, subdivided according to different groups of goods and countries of origin, in euros. The tool then calculates the emissions that occur in the supply chain worldwide. The data entered remains anonymous and is not stored, because purchasing data is particularly confidential for companies. Accordingly, companies can also specify scaled purchasing data so that absolute values can remain with the company. The purchased goods are combined into groups of goods anyway and can no longer be identified in individual cases.

The calculation of supply chain emissions is based on average values for the groups of goods from the respective countries and, of course, does not represent the real supply chain of a company. But the figures serve as a good estimate and hotspot analysis, with which many conclusions can be drawn, e.g., whether certain raw materials or intermediate products should be sourced from other countries in the future. Corporate purchasing departments will increasingly have to deal with these issues.

Even more accurate estimates would be obtained if suppliers also used the scope3analyzer for balancing. Because they would then accurately determine their Scope 1 and 2 emissions, and only their supply chain would be estimated with average values. You could go deeper and deeper in the supply chain and eventually even determine the exact Scope 3 emissions balance. Therefore, the tool is offered in both German and English.

After balancing, the real work begins: reducing emissions

But after balancing, the real work begins, namely reducing emissions. Monetary compensation or the mere purchase of green electricity, whose origin is often dubious, is not a solution in the long term. In the long term, it only makes sense to switch to energy and material-efficient technologies, to renewable energies and to low-emission upstream products. Every company can play its own part in this.

Magazine article about Pforzheim University

Tracking carbon footprint in the supply chain

You might also be interested in

Sustainability

The manufacturing industry has a responsibility to reduce its environmental footprint. Legal requirements and growing social pressure have set a process of rethinking in motion: corporate leaders see a need to reassess the environmental impact of their work.

Read more

Study Green Transformation 2022

On a total of 56 pages, the study provides a detailed insight into this industry’s sustainability strategy. In addition, we compare the results with important findings from the study “Green Transformation in the Automotive Industry” conducted last year. Expert reports from Munsch Chemie-Pumpen GmbH and TRUMPF Machine Tools offer exciting impulses directly from the field….

Read more

The seed has sprouted

From development to sales – agricultural technology specialist LEMKEN is facing the challenges of lean management in terms of quality, delivery reliability and costs as well as increasing complexity in processes and products. The “lemken excellence” initiative is the key to unlocking potential and empowering employees for this long-established company from alpen on the lower rhine river, germany. The close and early involvement of controlling in the project ensures company-wide acceptance, target orientation, and quantifiability.

Read more